SEZ Technopolis Moscow has developed a new type of refr...

Innovative refrigerators for supermarkets were developed by a tenant of the special economic zone of Moscow - the company OMEX. The equipment has interchangeable elements. Compressors that provide low temperature are removable and are made in the form of cassette units reducing the time and cost of servicing as informed by Gennady Degtev, CEO of SEZ Technopolis Moscow.

“The technical solution of Moscow engineers allows servicing refrigerators outside the store - by sending only the cassette module to the service. This method reduces the time and cost of servicing refrigerators. In addition, the use of removable elements significantly increases the effective capacity of the refrigerator - by 30-50% in comparison with analogues. The development has already been registered and has brought the company six patents. The release of new commercial equipment will begin at one of the manufacturer's sites in February 2021. Subsequently, production will be transferred to Alabushevo site of SEZ Technopolis Moscow, where a new company plant will be built in 2023”, said Gennady Degtev.

According to the CEO of OMEX Grigory Karneev, the company plans to produce about three thousand refrigerators with cassette units per year.

“The equipment is presented in several series - from refrigerated display cases to low-temperature cabinets. It provides energy savings of over 15 percent. Refrigerators can also work as independent equipment, or can be integrated into complex supermarket equipment systems according to the “smart store” principle, when all energy-consuming devices are interconnected and operate under specified mode. Earlier, using this technology, OMEX has already equipped more than 100 stores of the Pyaterochka chain, which allowed them to reduce their total energy consumption by 4.9 percent”, he added.

Refrigerated display cases from the resident of SEZ Technopolis Moscow can be found in supermarkets of the X5, SPAR, Intertorg, Karusel, Verny, Auchan and others chains. The manufacturer's line includes not only refrigeration equipment for trade objects, but also industrial units. During 2019-2020, the company produced more than 17 thousand units of products of various names.

Press service of the SEZ "Technopolis Moscow"

Phone: +7 916 516-15-46

Mail: pr@technomoscow.ru

Subscribe to the SEZ "Technopolis Moscow" in social networks, follow the main news of the SEZ in telegram-channel and receive all the most important news delivered to your mail in our weekly newsletter.

Residents of the SEZ Technopolis Moscow entered the Nat...

At the end of 2020, three tenants of the special economic zone Technopolis Moscow were included in the National rating of Russian fast-growing technology companies TechUspekh. Enterprises were included in the main rating, and also marked in the categories "The Best Growth", "Innovative" and "Export potential" as informed by Gennady Degtev, CEO of SEZ Technopolis Moscow.

The TechUspech rating has existed since 2012, organized by the Russian Venture Company. This year the rating included 107 companies from 24 regions of Russia, including more than 45 enterprises in the capital. Over the past four years, the rating has also served as a base for searching and selecting Russian technology companies to participate in the priority project of the Ministry of Economic Development of Russia “Support for private high-tech companies-leaders” (“National Champions”).

Residents of the capital's SEZ - the companies Profotech and NCC, located in Pechatniki, as well as the Laboratory of Microdevices, localized in Alabushevo, were included in the main TechUspech rating among enterprises with revenues of up to 800 million rubles. The companies are engaged in the production of optical transformers, composites and inertial navigation systems. Also, enterprises were marked in the categories "The Best Growth ", "Innovative" and "Export potential", said Gennady Degtev.

The products of the Profotech company can be found at the largest Russian power facilities. NCC composites are used in the production of auto components, fittings, drone fuselages, mobile road surfaces, fiberglass railings, protective cases for gas pipelines and metro cars. Inertial navigation systems of the Microdevices Laboratory are used for unmanned vehicles and aircraft, satellite antenna and geodesy.

Also, the developments of the tenants are actively exported to the CIS countries, Europe, Latin and North America, as well as Asia. These include Japan, Switzerland, USA, India, Mexico, Belarus, Turkey, Kazakhstan and Uzbekistan.

Press service of the SEZ "Technopolis Moscow"

Phone: +7 916 516-15-46

Mail: pr@technomoscow.ru

Subscribe to the SEZ "Technopolis Moscow" in social networks, follow the main news of the SEZ in telegram-channel and receive all the most important news delivered to your mail in our weekly newsletter.

Resident of the SEZ Technopolis Moscow will invest more...

The company TZMOI (Tyumen plant of medical equipment and instruments) received the status of a resident of the special economic zone Technopolis Moscow at the end of 2020 and in 2021 plans to invest more than 20 million rubles in the expansion of production as informed by Alexander Prokhorov, Head of the Department for Investment and Industrial policy of Moscow.

“The enterprise produces sterilizers, disinfection and washing equipment, devices for the disinfection of medical waste and other equipment for infection control. At the SEZ site in Pechatniki from 2015 to 2019, the company successfully completed the first stage of production localization. This year the company plans to start the second stage, having invested 20.6 million rubles”, pointed out Alexander Prokhorov.

The TZMOI project contributes to the development of a segment of high-tech production of medical equipment on the territory of the special economic zone and will give the city more than 30 new jobs underlined Gennady Degtev, CEO of SEZ Technopolis Moscow.

“With the expansion of production, the range of manufactured equipment will be increased and the share of imported components will be reduced. The obtained resident status will allow the company to work with maximum efficiency, using the benefits and preferences of the capital's SEZ”, stressed the Head of the special economic zone.

JSC TZMOI is part of the Pharmstandard-medtekhnika group. The company plans to further develop production and additionally expand the range of equipment for infection control added Alexey Zezulya, Director of the parent organization.

“In 2020, the company supplied more than 300 units of equipment for disinfection and sterilization to medical institutions, including hospitals for patients with coronavirus infection. The deliveries covered seven regions of Russia. Further expansion will increase the geography of the company's presence and improve the level of equipment of Russian hospitals, while cooperation with SEZ Technopolis Moscow will help solve these problems more efficiently”, underlined the Head of the company.

Press service of the SEZ "Technopolis Moscow"

Phone: +7 916 516-15-46

Mail: pr@technomoscow.ru

Subscribe to the SEZ "Technopolis Moscow" in social networks, follow the main news of the SEZ in telegram-channel and receive all the most important news delivered to your mail in our weekly newsletter.

SEZ Technopolis Moscow has developed an innovative solu...

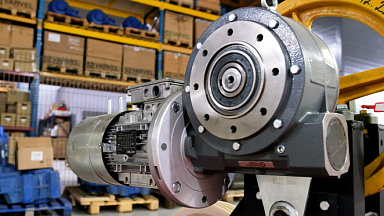

The new elevator winch was created by the company STC Drive Technique located in the capital's special economic zone. The development is two times lighter than its counterparts, and the service life is designed for at least 20 years as informed by Gennady Degtev, CEO of SEZ Technopolis Moscow.

The winch is the key device in the elevator design that raises and lowers the car. Its characteristics affect ride comfort, noise level and power consumption.

“The development is primarily aimed at import substitution. With limited supply in the domestic market Russian elevator companies mainly use foreign-made winches. The new device of the enterprise has been successfully tested at one of the elevator plants, it is two times lighter than analogues, corresponds to the "A" class of energy efficiency and has every chance to fill the deficit of Russian products in the industry”, said Gennady Degtev.

According to Dmitry Krasnov, CEO of STC Drive Technique in addition to durability and economy, the device is convenient in operation, since it does not require changing the oil in its elements, does not take up much space in the engine room, makes less noise and has a number of improved technical characteristics.

“The development is a proper response to the needs of the Russian elevator industry and housing and communal services, where, according to experts, more than 160 thousand elevators require replacement and modernization. Specializing in electric drives, the company has created a turnkey solution for the elevator industry. A patent for an invention has already been received. The product will be launched into serial production after final tests in the summer of 2021”, he added.

Press service of the SEZ "Technopolis Moscow"

Phone: +7 916 516-15-46

Mail: pr@technomoscow.ru

Subscribe to the SEZ "Technopolis Moscow" in social networks, follow the main news of the SEZ in telegram-channel and receive all the most important news delivered to your mail in our weekly newsletter.

A new resident will open a microchip design center in t...

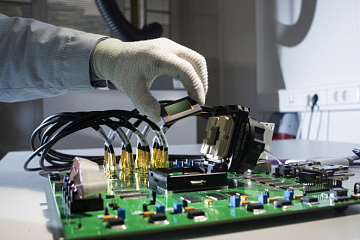

The resident of SEZ Technopolis Moscow - ELVIS opens a microcircuit design center at the Alabushevo site in the first half of 2021. The company will set about the development of element base for aviation and space technology, as well as the design of microcircuits for ICT as informed by Alexander Prokhorov, Head of the Department for Investment and Industrial policy of Moscow.

“The company is to occupy nine thousand square meters in an innovative laboratory and industrial building located at the Alabushevo site. Now the enterprise is also localized in Zelenograd, it employs more than 500 people who annually produce about 25 thousand microcircuits and security systems. The move will give the resident the opportunity to expand its staff to 900 employees and increase its production capacity four times by 2030, to almost 100 thousand electronic products per year.”, said the Head of the Department.

The company develops systems on a chip based on its own design platform "MULTICOR", as well as high-tech security systems. Among them are systems for telecommunications equipment and radiation-resistant microcircuits for spacecraft.

“The enterprise is one of the leading developers and manufacturers of microelectronics not only in the capital, but also in the country. Among the company's clients are more than 500 companies from various industries, as well as foreign IT partners from the UK, Korea, Switzerland, Bulgaria. Last year, the Ministry of Industry and Trade of Russia identified the company as one of the key executors of the Strategy for the Development of the Electronic Industry of the Russian Federation for the Period up to 2030”, underlined Gennady Degtev, CEO of SEZ Technopolis Moscow.

Press service of the SEZ "Technopolis Moscow"

Phone: +7 916 516-15-46

Mail: pr@technomoscow.ru

Subscribe to the SEZ "Technopolis Moscow" in social networks, follow the main news of the SEZ in telegram-channel and receive all the most important news delivered to your mail in our weekly newsletter.

Resident of SEZ Technopolis Moscow will start productio...

A portable artificial lung ventilation device for patients with adverse events after coronavirus infection is being developed by a tenant of the Moscow special economic zone, the company Chirana +. The first prototype of the ventilator will appear at the end of August 2021 as informed by Alexander Prokhorov, Head of the Department for Investment and Industrial policy of Moscow.

“The pandemic has made ventilators one of the most demanded types of medical equipment. The industry has focused to increase the volume of their production, as well as component parts for them. The manufacturer plans to launch the production of portable devices that will be useful not only in the emergency assistance, but also in the following rehabilitation of patients with Covid-19”, said Alexander Prokhorov.

The new ventilator is designed to help patients with Covid-19 lung disease in a hospital, as well as for seriously ill patients treated at home. In addition, mobile devices will be in demand in ambulances.

“The is a joint project with Dutch partners - they are working on the engineering solution to be implemented at SEZ Technopolis Moscow site with maximum import substitution. In this regard, the manufacturer is looking for the possibility of industrial cooperation with the tenants of the special economic zone for the production of high-tech electronic components”, said Gennady Degtev, CEO of SEZ Technopolis Moscow.

Currently, Chirana +, in close cooperation with the Dutch company Demcon, is working on design solutions that allow combining the Dutch turbine module with Russian-made components in order to ensure the necessary operational parameters of the future lung ventilator, specified Artem Shimco, Deputy CEO on Development of the company.

“The innovative module will make the new ventilators portable weighing only 3 kg and applicable in ambulance before the patient is admitted to the hospital. After testing and state registration, the products will go into serial production”, said Artem Shimco.

The Chirana + company, which produces artificial lung ventilation devices, has been operating at the site in Pechatniki since mid-2018, in 2020 it received the status of a resident of SEZ Technopolis Moscow. The enterprise's capacities allow over 300 units of medical equipment per year.

Press service of the SEZ "Technopolis Moscow"

Phone: +7 916 516-15-46

Mail: pr@technomoscow.ru

Subscribe to the SEZ "Technopolis Moscow" in social networks, follow the main news of the SEZ in telegram-channel and receive all the most important news delivered to your mail in our weekly newsletter.

SEZ Technopolis Moscow has developed a robotic system f...

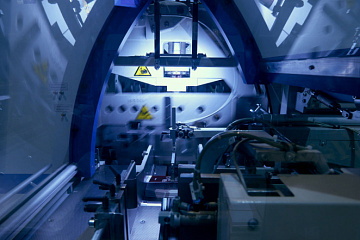

Bitrobotics, a resident of the special economic zone Technopolis Moscow, has developed a high-tech robotic system for stacking sliced cheese for dairy production in St. Petersburg. The solution will ensure the stable quality of the manufactured product and increase the production efficiency as informed by Alexander Prokhorov, Head of the Department for Investment and Industrial policy of Moscow.

“Advanced digital solutions offered by Moscow companies are used in various industries. They help to cut costs, increase line productivity, and reduce scrap. Thus, a resident of SEZ Technopolis Moscow, Bitrobotics, is currently implementing a new project for the Neva Milk Group of Companies on robotic stacking of sliced cheese. In addition, the company's solutions are presented in our "Technology Bank" - a specialized platform for the latest developments, allowing enterprises to quickly select the necessary technology for implementation and adjust its parameters for their tasks and business profile. In total, there are already about 40 solutions presented there”, said the Head of the Department.

The unique feature of the development is its unified production elements. 3D machine vision scans and determines the presence of cheese at the product intake, and the delta robot captures, transfers and places the cheese on the conveyor. Thanks to its high motion accuracy and kinematics, the delta robot provides for maximum productivity in high-speed gripping and handling operations.

“The pocket-sized delta robot is easily integrated into the production line. The process itself takes place “behind the glass”, ruling out direct contact with the product and keeping the line section clean. Commissioning is planned for February 2021”, revealed Gennady Degtev, CEO of SEZ Technopolis Moscow.

The development company has been working in SEZ Technopolis Moscow since 2019, and its solutions have already been implemented at large enterprises of the Moscow industry. The new project will expand the geography of the manufacturer's market reach.

“The pandemic has accelerated the pace of industrial robotics development. Many enterprises are looking for the most relevant solutions in order to maintain their position in the market and increase production efficiency. Up to now companies did not see the need for automation of technological processes, while now this issue is becoming urgent. By 2025, robots will perform most of the operations in manufacturing”, pointed out Svyatoslav Stesin, Bitrobotics CEO.

The company is currently preparing to set up the a production site in Pechatniki, scheduled for the spring of 2021. The status of a resident obtained in 2019 and the localization of production in the special economic zone Technopolis Moscow opened the access to significant preferences: a preferential rate of property and transport tax, reduced income tax and duty-free imports.

Press service of the SEZ "Technopolis Moscow"

Phone: +7 916 516-15-46

Mail: pr@technomoscow.ru

Subscribe to the SEZ "Technopolis Moscow" in social networks, follow the main news of the SEZ in telegram-channel and receive all the most important news delivered to your mail in our weekly newsletter.

In the SEZ Technopolis Moscow created a robot for the a...

Special Design and Technology Bureau of Applied Robotics (SKTB PR), a tenant of SEZ Technopolis Moscow have developed a mobile robotic complex for dismantling the graphite stack of carbon-graphite reactors as informed by Gennady Degtev, CEO of SEZ Technopolis Moscow.

The complex consists of a mobile robot, a remote control and a magazine case with a special electric cutting tool. The development makes it possible to remotely carry out dismantling work on carbon-graphite reactors, which were previously widely used at nuclear power plants or industrial facilities, for example, in the manufacture of weapons. Reactors of this type are now being decommissioned.

“The development of the resident of the SEZ Technopolis Moscow excludes the presence of people in the zone with increased radiation. The operator remotely controls the robot, and with the help of a video system, which is part of the complex, controls the work. The robot manipulator is capable of lifting and carrying up to 100 kg, which is sufficient to remove the graphite blocks. Since the end of last year, the development has been tested at the Experimental Demonstration Center of Carbon-Graphite Reactors”, said Gennady Degtev.

SKTB PR has also created a special stand simulating the graphite stack and the main elements of the reactor's metal structures. The first tests of the robot were carried out at the stand and proved its functionality. In the future, SKTB PR will hand over the stand to the customer for operators to practice the most complicated dismantling operations and improve their skills with the help of a robot.

SKTB PR actively cooperates with the nuclear industry. For example, in September, a robotic system created in SEZ Technopolis Moscow was sent to the Leningrad NPP for the repair of spent nuclear fuel storage pools of a new type of nuclear power plant.

Press service of the SEZ "Technopolis Moscow"

Phone: +7 916 516-15-46

Mail: pr@technomoscow.ru

Subscribe to the SEZ "Technopolis Moscow" in social networks, follow the main news of the SEZ in telegram-channel and receive all the most important news delivered to your mail in our weekly newsletter.

Resident of the SEZ Technopolis Moscow will invest more...

The Rada-Pharma company at the end of 2020 received the status of a resident of the special economic zone and plans to invest more than 40 million rubles in the launch of a new production line by 2022. The company specializes in the production of drugs and medical devices based on chlorophyll for photodynamic therapy, which is used in the treatment of oncological, gynecological and dermatological diseases as informed by Alexander Prokhorov, Head of the Department for Investment and Industrial policy of Moscow.

The method of photodynamic therapy is based on the selective accumulation of the active drug substance in malignant neoplasms, which are destroyed when interacting with laser radiation of a certain wavelength, without damaging healthy cells.

“Now Rada-Pharma produces about 12.5 thousand drugs and medical devices annually, and by the end of 2026, the commissioning of a new line will increase production by a third, to 17 thousand pieces. Currently, the share of Rada-Pharma in the domestic market of drugs for photodynamic therapy is about 66 percent”, said the Head of the Department.

The status of a resident of the special economic zone Technopolis Moscow will give the company the opportunity to significantly save on taxes and other obligatory payments every year: the company will have access to a reduced income tax, duty-free imports and a zero rate on property and transport. The company plans to use the funds saved in the budget to improve material and technical support, create new developments and training programs.

Thanks to investments, the resident also plans to increase its share in the domestic market said Gennady Degtev, CEO of SEZ Technopolis Moscow.

“Rada-Pharma has been localized on the territory of the special economic zone since 2014. The company's products are supplied to public hospitals, private clinics and pharmacies in more than 50 regions of the country. Obtaining resident status and all tax preferences, introducing a new line of equipment and keeping prices by a quarter lower than those of competitors will allow the company to increase its share in the Russian market of drugs for photodynamic therapy up to 70 percent”, specified Gennady Degtev.

Press service of the SEZ "Technopolis Moscow"

Phone: +7 916 516-15-46

Mail: pr@technomoscow.ru

Subscribe to the SEZ "Technopolis Moscow" in social networks, follow the main news of the SEZ in telegram-channel and receive all the most important news delivered to your mail in our weekly newsletter.

An innovative environmental monitoring station was inst...

Mosecomonitoring has installed an innovative automatic station for ecological monitoring on the territory of the special economic zone Technopolis Moscow in early January. The station continuously measures the concentration of carbon monoxide, hydrogen sulfide, nitrogen oxides, suspended particles, methane, as well as meteorological parameters.

Anton Kulbachevsky, the Head of the Department for Environmental Management and Protection pointed out that today Moscow is the only region in Russia where such continuous environmental monitoring is carried out.

“Monitoring stations display the results of monitoring on an electronic display in real time, the first sample is installed in the territory of high-tech and industrial production development - in the special economic zone Technopolis Moscow in Pechatniki. The location of the innovation station wasn’t a random choice. The territory near the Tekstilshchiki metro station is located on the border of two districts under significant technogenic load from intensive traffic flows along Volgogradsky Prospekt and Lyublinskaya Street”, said Anton Kulbachevsky.

The station will not only help to track ecological indicators, but will also spark the interest of schoolchildren and students who visit the special economic zone, added Gennady Degtev, CEO of SEZ Technopolis Moscow.

“SEZ Technopolis Moscow is one of the key centers of innovation development in the city. Let me remind you that high-tech enterprises are a new type of industry, which not only implements advanced developments, but also demonstrates responsible attitude to the environment, so we are pleased to become a part of this project. The station is located on Shosseynaya street next to the Tekstilshchiki TPU under construction. It changes color depending on the results of measuring the impurities concentration in the air, and the indicators themselves are displayed on the LED display. The data is updated every 20 minutes. At the same time, the walls near the station are transparent, which allows the townspeople, to get acquainted with its equipment. Its design will be especially interesting for schoolchildren and students who visit the enterprises of the capital's SEZ for practice, study or excursions”, said Gennady Degtev.

The spread of stations of this type is reasonable mainly in places that are points of attraction for a large flow of citizens and guests of the capital, thus, the station will be in sight of a large number of people.

Moscow eco-monitoring automatic stations are constantly updated - over the past 10 years Mosecomonitoring has carried out a wide renewal of its instrument park, and 24 new stations have been put into operation. In 2020, 13 automatic stations were replaced. In 2021, two new stations will be installed in the Nekrasovka and Western Degunino districts.

Press service of the SEZ "Technopolis Moscow"

Phone: +7 916 516-15-46

Mail: pr@technomoscow.ru

Subscribe to the SEZ "Technopolis Moscow" in social networks, follow the main news of the SEZ in telegram-channel and receive all the most important news delivered to your mail in our weekly newsletter.

By 2023, a new production of medical devices will appea...

The resident of SEZ Technopolis Moscow, the research and production association Penta Group, which is part of the Mediana group of companies, will construct a plant at the Alabushevo site for the production of consumables for ventilators, blood transfusion systems and liquids, as well as containers for blood collection. Investments in the project will amount to 1.69 billion rubles, the launch is scheduled for 2023 as informed by Vladimir Efimov, Vice-Mayor of Moscow for Economic policy and Land-property affairs.

“A plant for the production of medical devices with a total area of 18 thousand m² will appear on a land plot of 3.4 ha at the Alabushevo site of SEZ Technopolis Moscow. The construction start is expected at the end of 2021, the production launch - in 2023. The investor will invest 1.69 billion rubles in the localization of manufacturing by the end of 2023 and create more than 270 jobs”, said the Vice-Mayor.

According to Alexander Prokhorov, Head of the Department for Investment and Industrial policy of Moscow the products of the tenant will be made with the use of medical PVC-plasticates granules of its own production.

“During the implementation of the project, the company plans to reach an annual production volume of at least 480,000 breathing circuits and 1.4 million breathing filters for ventilators. Besides, the products will be made using their own medical plastic”, he added.

According to Gennady Degtev, CEO of SEZ Technopolis Moscow the plant will help to increase the share of domestic products in the internal market.

“The company's products fully meet the objectives of import substitution - its products are almost entirely made from domestic raw materials. In addition, when the company received the status of a resident of SEZ Technopolis Moscow in December 2020, significant tax preferences became available to it: a preferential income tax rate, a zero rate of property, land and transport tax for 10 years from the moment of obtaining the status, and also access to duty free imports”, he pointed out.

Press service of the SEZ "Technopolis Moscow"

Phone: +7 916 516-15-46

Mail: pr@technomoscow.ru

Subscribe to the SEZ "Technopolis Moscow" in social networks, follow the main news of the SEZ in telegram-channel and receive all the most important news delivered to your mail in our weekly newsletter.

Printing houses of SEZ Technopolis Moscow printed more ...

On the territory of the Moscow special economic zone, there are several printing houses involved in digital printing. They printed over 5 million copies in 2020 as informed by Gennady Degtev, CEO of SEZ Technopolis Moscow.

“Organizations such as T8, Photoexpert, Onebook and Commandp are located in the special economic zone. In total, the circulation of published books in 2020 exceeded 5 million copies. About 4 million copies of books were printed in one printing house "T8" alone. These are publications of various genres - from popular classics to modern psychology and educational literature. The company specializes in printing short runs in a fully automatic mode using high technologies. The SEZ of Moscow values companies with unique solutions and develops infrastructure for their comfortable work”, pointed out Gennady Degtev.

The technique the company uses can print ultra-small runs on a production scale, with a minimum of staff involved. Printers use cloud-based virtual storage, digital content management and digital production. The product sales market is over 35 thousand stores around the world. T8 also provides for the “print on demand” technology, when a book goes to print if it already has a customer on the platforms of online stores. “Book on demand” can be purchased at any online bookstore without direct contact with the publisher. It takes 24 hours to produce and deliver it to the addressee. The technology allows you to print books in one copy at the cost of a large batch.

Such opportunities are unique today, they allowed the company to successfully overcome the challenges of 2020, says its CEO Sergey Latyntsev.

“In the first wave of the pandemic, 70 percent of publishing houses in the country froze book printing. The rest of the publishers either postponed printing or printed only part of their publishing plans. Those who have continued to produce books have shown great interest in print-on-demand for books below 500 copies. It was this trend that allowed T8 to get out of the pandemic without losses and to maintain production volumes in 2020 at the level of the previous year. In their authors have the opportunity to be published and remain in demand thanks to this solution. The printing house constantly works with such publishing houses and organizations as Alpina Business Books, Publishing House Piter, Ripol Classic Group of Companies, Lomonosov Moscow State University, Moscow Book Publishing House and others”, he summarized.

Press service of the SEZ "Technopolis Moscow"

Phone: +7 916 516-15-46

Mail: pr@technomoscow.ru

Subscribe to the SEZ "Technopolis Moscow" in social networks, follow the main news of the SEZ in telegram-channel and receive all the most important news delivered to your mail in our weekly newsletter.

Ashkhen Hovsepyan became the official ambassador of Wom...

Ashkhen Ovsepyan, CEO of the company SIU System had been officially appointed an ambassador of the international organization Women in 3D printing in Russia.

Engaged in the supply of industrial equipment to Russia, she watched the development of 3D technologies and was sure that they were the future. In 2013, the entrepreneur opened the first 3D printer store, which became the starting point for determining the future development of her company.

Ashkhen decided to focus on industrial 3D printing. Today, SIU System provides 3D printing services and supplies equipment for aviation, mechanical engineering, space, nuclear industry, medicine and other industries.

The entrepreneur believes in the success of 3D printing, because it makes an unbearable contribution to the development of production: thanks to 3D technologies, today it is possible to do what was impossible yesterday. In her work, Ashkhen interacts with the founders of 3D printing, which allows her to be aware of the latest developments.

Women in 3D Printing supports, inspires and promotes women in additive manufacturing. The community is increasing the visibility of women leaders in the additive manufacturing industry and engaging more and more newcomers to use 3D printing technologies.

As an ambassador, Ashkhen Ovsepyan represents the organization at the local level, is responsible for events of various formats dedicated to 3D printing, as well as for creating a community in Russia.

Press service of the SEZ "Technopolis Moscow"

Phone: +7 916 516-15-46

Mail: pr@technomoscow.ru

Subscribe to the SEZ "Technopolis Moscow" in social networks, follow the main news of the SEZ in telegram-channel and receive all the most important news delivered to your mail in our weekly newsletter.

SEZ residents increased production by 25% in 2020

For nine months of 2020, residents of the special economic zone Technopolis Moscow produced goods worth 12.5 billion rubles, which is a quarter more than the same period last year. More than 70 percent of the total volume was provided by manufacturers of electronics and optical solutions informed Vladimir Efimov, Vice-Mayor of Moscow for Economic policy and Land-property affairs.

SEZ residents produce electronic products, optical solutions, medical and energy-efficient equipment, nanomaterials, inspection solutions, medicines, disinfecting and sterilizing equipment, measuring instruments, oilfield service and educational equipment, water, air and surface disinfection systems. Besides, data and design centers, a plastic waste processing plant are located in the capital's SEZ.

“In just nine months of this year, the residents of the special economic zone produced goods worth 12.5 billion rubles, which is a quarter more than in the same period last year. Microelectronics enterprises became the leaders - they produced products for a total amount of about 9.4 billion rubles. Second rank manufacturers of drugs, medical equipment and products with a production volume of 908 million rubles. During the entire existence of the special economic zone, the volume of manufactured products reached almost 76 billion rubles”, mentioned the Vice-Mayor.

He added that the growth in production of SEZ residents is due to an increase in demand for their products.

Microelectronics manufacturers also became leaders in the number of new jobs added Alexander Prokhorov, Head of the Department for Investment and Industrial policy of Moscow.

“For 9 months of 2020, SEZ residents have created about a thousand jobs. Almost half of the new employees joined microelectronics enterprises during this period. About 140 people work in companies focusing on energy efficient technologies, another 100 people work in the production of drugs and medical devices. It should be noted that the average salary at the SEZ enterprises for that period amounted to 77.8 thousand rubles”, specified the Head of the Department.

Favorable working conditions are ensured by the SEZ resident status underlined Gennady Degtev, CEO of SEZ Technopolis Moscow.

“The benefits that companies receive open access to duty-free imports, a zero rate of property and transport tax, and a preferential rate on profits. Thus, in the three quarters of 2020, residents saved 687 million rubles”, said Gennady Degtev.

Press service of the SEZ "Technopolis Moscow"

Phone: +7 916 516-15-46

Mail: pr@technomoscow.ru

Subscribe to the SEZ "Technopolis Moscow" in social networks, follow the main news of the SEZ in telegram-channel and receive all the most important news delivered to your mail in our weekly newsletter.

An open day was held at the Center for Industrial Robot...

An Open Day was held at the ABB Russia Industrial Robotics Center located in the special economic zone Technopolis Moscow. In the renovated showroom, the capabilities of the most popular models of the center's robots were demonstrated as informed by Gennady Degtev, CEO of SEZ Technopolis Moscow.

“The entire exposition of the center is of interest to specialists - a palletizing robot, a delta robot, a collaborative robot YuMi, as well as robots designed for milling and welding. The showroom with the equipment is just a part of the ABB Russia Industrial Robotics Center, opened in 2016, which comfortably complements the ecosystem of the Moscow SEZ, meeting the demands of innovative industrialists for new technology and knowledge. The Technopolis Moscow site also houses an engineering and service center for industrial automation using robots and a training center where enterprise specialists are trained in working with industrial robotic systems and industrial automation systems", said Gennady Degtev.

A striking example of the educational work of the Center is the robotics programming competition for students. The winners will be announced at the end of December this year. Finalists will receive certificates for training, and the most technologically advanced and non-standard projects will appear on the PRO Robots YouTube channel, where their authors will be able to tell about themselves and their work.

In addition to the education, the Industrial Robotics Center directly works with enterprises, carries out the design of robotic systems.

“The main task of our Industrial Robotics Center is to conduct a technical audit and find the most effective solutions for specific customers. Based on the expertise of our specialists and the international experience of the company, we successfully solve these problems”, said Alexander Novoselov, the Head of Robotics Department at ABB Russia.

ABB is a global technology leader in electrical, robotics, automation and drive technology. It has been working in Russia for over 30 years. The company's robots find their application in various industries and are used to automate various types of operations: machining, maintenance of a machine tool park, moving bulky goods, assembling small electronic components, work in "clean rooms" of industrial complexes of the pharmaceutical, electronic and food industries.

About 1.5 thousand of the company's robots "work" at Russian enterprises. Significant projects include quality control of insulin pens production at the Novo Nordisk plant in the Kaluga Region, palletizing of refractory products at the Satka production site of the Magnezit Group in the Chelyabinsk Region, assembly and soldering of flexible loops of electronic boards for StarLine automobile security systems in the Leningrad Region and a robotic line for flanging body elements at the Renault plant in Moscow.

Robots are also very active in the food industry. Thus, the company's robotic systems automated the production process of the Cherkizovo meat processing plant in Kashira, the Vologda dairy plant and the MolProduct plant in the Moscow region, as well as the Danone plant in Chekhov near Moscow and the Unilever plant in the Tula region.

The introduction of robotic solutions allows companies to increase productivity, improve the quality of technological operations, transfer workers from hazardous to health and repetitive work to more intelligent and important tasks, and optimize the workspace. Thanks to robotic systems and automation, production reaches a completely new level, corresponding to "Industry 4.0". Thus, according to the company's experts, depending on the initial level of production automation, the customer can increase the productivity of industrial lines from 25% to multiples.

Press service of the SEZ "Technopolis Moscow"

Phone: +7 916 516-15-46

Mail: pr@technomoscow.ru

Subscribe to the SEZ "Technopolis Moscow" in social networks, follow the main news of the SEZ in telegram-channel and receive all the most important news delivered to your mail in our weekly newsletter.